Concept and Realization of an Assembly Line

Objectives and Scope

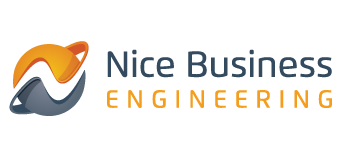

The increase in production volumes forced the management to rethink the organisation in the assembly department.

Nicebe is in charge of establishing a concept to move from a “shopfloor” type organisation to an “assembly line” type organisation in line with future volumes and optimised operational processes.

A concept on a surface area of 2’000 m2 has been established in a participative way with the production teams.

Project

Project span : 2 months

Analysis of the product structure (BOM cross-referenced with the operating ranges)

Assembly cell definition for assemblies

Definition of the central assembly line with its balanced steps

Definition of resources (production and storage areas, infrastructure, transport chassis)

Populating the lines according to the volume scenarios to be produced

Definition of training needs based on the competency matrix.

Achievements

For the same surface area, the production capacity tripled, the lead times were divided by four (1 month to 1 week).